you position:Home > us energy stock > us energy stock

Fanuc US Stock Location: Optimizing Your Manufacturing Process

![]() myandytime2026-01-20【us stock market today live cha】view

myandytime2026-01-20【us stock market today live cha】view

info:

In today's fast-paced manufacturing industry, efficiency and precision are key. One of the critical components in achieving these goals is the Fanuc US stock location. This article delves into the importance of stock location, how to optimize it, and the benefits it brings to your manufacturing process.

Understanding Fanuc US Stock Location

Fanuc is a leading manufacturer of robotics and CNC machines, known for their reliability and advanced technology. The Fanuc US stock location refers to the strategic placement of components, materials, and tools within a manufacturing facility. Properly managing this location can significantly improve your production process.

Why is Stock Location Important?

Efficient stock location is crucial for several reasons:

- Reduced Lead Times: By keeping the materials and components you need within easy reach, you can reduce lead times and increase production speed.

- Reduced Labor Costs: With the right stock location, your employees can spend less time searching for materials and more time on productive tasks.

- Improved Quality Control: Easy access to stock allows for better quality control, as you can quickly identify and address any issues with the materials or components.

- Increased Flexibility: With a well-organized stock location, you can easily adapt to changes in production requirements.

Optimizing Your Fanuc US Stock Location

To optimize your stock location, consider the following tips:

- Analyze Your Production Process: Understand the flow of your production process and identify the materials and components that are used most frequently.

- Implement a Systematic Approach: Use a numbering system or color-coding to organize your stock. This will make it easier to locate and identify items.

- Utilize Storage Solutions: Invest in storage solutions such as shelves, bins, or cabinets to keep your stock organized and easily accessible.

- Regularly Review and Adjust: Regularly review your stock location and make adjustments as needed to ensure it continues to meet your production requirements.

Case Study: Company A’s Transformation

Company A, a manufacturer of electronic components, faced several challenges due to inefficient stock location. They had difficulty finding the materials they needed, which resulted in increased lead times and labor costs. After implementing a systematic approach to their stock location, they saw a significant improvement:

- Lead Times Decreased by 20%: With materials and components easily accessible, they could start production faster.

- Labor Costs Decreased by 15%: Employees spent less time searching for materials and more time on productive tasks.

- Quality Control Improved: With better access to stock, they could quickly identify and address any issues with the materials or components.

Conclusion

In conclusion, optimizing your Fanuc US stock location is crucial for improving your manufacturing process. By analyzing your production process, implementing a systematic approach, utilizing storage solutions, and regularly reviewing and adjusting your stock location, you can reduce lead times, labor costs, and improve quality control. Don't wait—start optimizing your stock location today and experience the benefits it brings to your business.

so cool! ()

last:Latest US Stock News: Key Developments and Market Insights

next:nothing

like

- Latest US Stock News: Key Developments and Market Insights

- US Government Buys Intel Stock: What You Need to Know

- Top 5 US Healthcare Stocks to Watch in 2023

- Highest Stock Market Earnings in One Year: US Companies Lead the Charge

- US Stock Honey Extractor: The Ultimate Guide to Efficient Beekeeping

- TRP US SM CP Core EQ TR D Stock: A Comprehensive Guide

- Unlock the Potential of TLT US Stock: Your Ultimate Guide

- Early Movers: Top US Stocks to Watch in 2023

- Reclaimed Wood Bulk Purchase: Northeastern US Supplier Stocks at Unbeatable Price

- Sino-US Stock Price: Understanding the Dynamic Interplay

- Sogo Us Stock Price: A Comprehensive Analysis

- Computershare Sale of Stock by Executor of Estate US: A Comprehensive Guide

hot stocks

Gas Stocks: A Lucrative Investment Opportunity

Gas Stocks: A Lucrative Investment Opportunity- When to Sell Stocks: A Comprehensive Guide for"

- Walmart Dividend: A Comprehensive Guide to Und"

- Top Gainers: Unveiling the Market's Most "

- Understanding the Value ETF: A Comprehensive G"

- Volatile Stocks: Understanding the Risks and R"

- What is Dividend Yield?"

- Undervalued Stocks: Unlocking Hidden Potential"

- Value Stocks: The Key to Long-Term Wealth Buil"

recommend

Fanuc US Stock Location: Optimizing Your Manuf

Fanuc US Stock Location: Optimizing Your Manuf

Sunniva Stock US: Unveiling the Potential of T

US Stock Market Performance on April 7, 2025:

Best US Day Trading Stocks: Unveiling the Hidd

Title: US Stock Market After Trump: A Comprehe

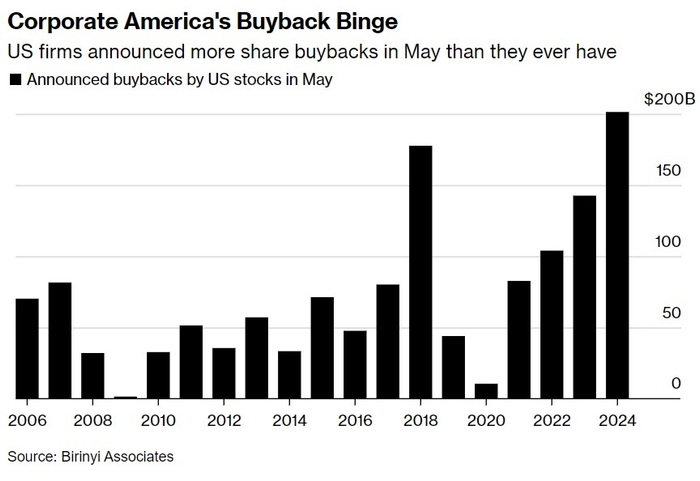

How Many US Companies Are Buying Back Their Ow

Moomoo US Stock Trading Fee: Comprehensive Gui

FLST US Stock Exchange: A Comprehensive Guide

Understanding US Capital Stock Securities: A C

The Costliest Stock in the US: A Deep Dive int

Trading US Stocks from Dubai: A Comprehensive

tags

-

TomorrowAprilFuturesRareGrowingUnderstaComprehensAllegedLNGExchangAcronymHolCanEssentialGoldClosedCannabisEarthPerExchange20182021IndianfromLo5130150NameTankAlternative4245GalChineseIslandStrategyPivotalDefinitioJonesDelhaizeManyA7IIISchwabCompletionMarCitizensFallEdibleMFCListDidNintendo2ndDaysNon-USBogleheOpenHolidaysBYDDelekSmallPurchaseRiskHighwaySixth-Gener2023LargestFoodTotal2019InsectAholdTimingstodshareShausaveruamerican10010miniliveAvnasdaqSustainaPharmaceCleaFuUnderaverage us stocks games silver etf us stock

like

- Asia-US Industrial Joint Stock Company: A Prom"

- US Stock Futures: Hot Stocks to Watch"

- Military Stocks: A Smart Investment for Savvy "

- Title: US Gypsum Stock: The Ultimate Guide to "

- Current US Stock Market Capitalization: Unders"

- Toys R Us Liquidation Stock Quotes: Your Ultim"

- Samsung Stock Traded in US: A Comprehensive Gu"

- US Rare Earth Company Stock: The Future of Adv"

- 3 Stock Exchanges in the US: A Comprehensive G"

- US Mint Proof Set Stock Photos: The Ultimate G"